Our specialized departments

Over the years, we have always chosen to invest in product quality: our components are made from selected raw materials and accurate control systems are employed during every processing stage. We also dedicate special care into the research of solutions targeted on optimizing our production processes.

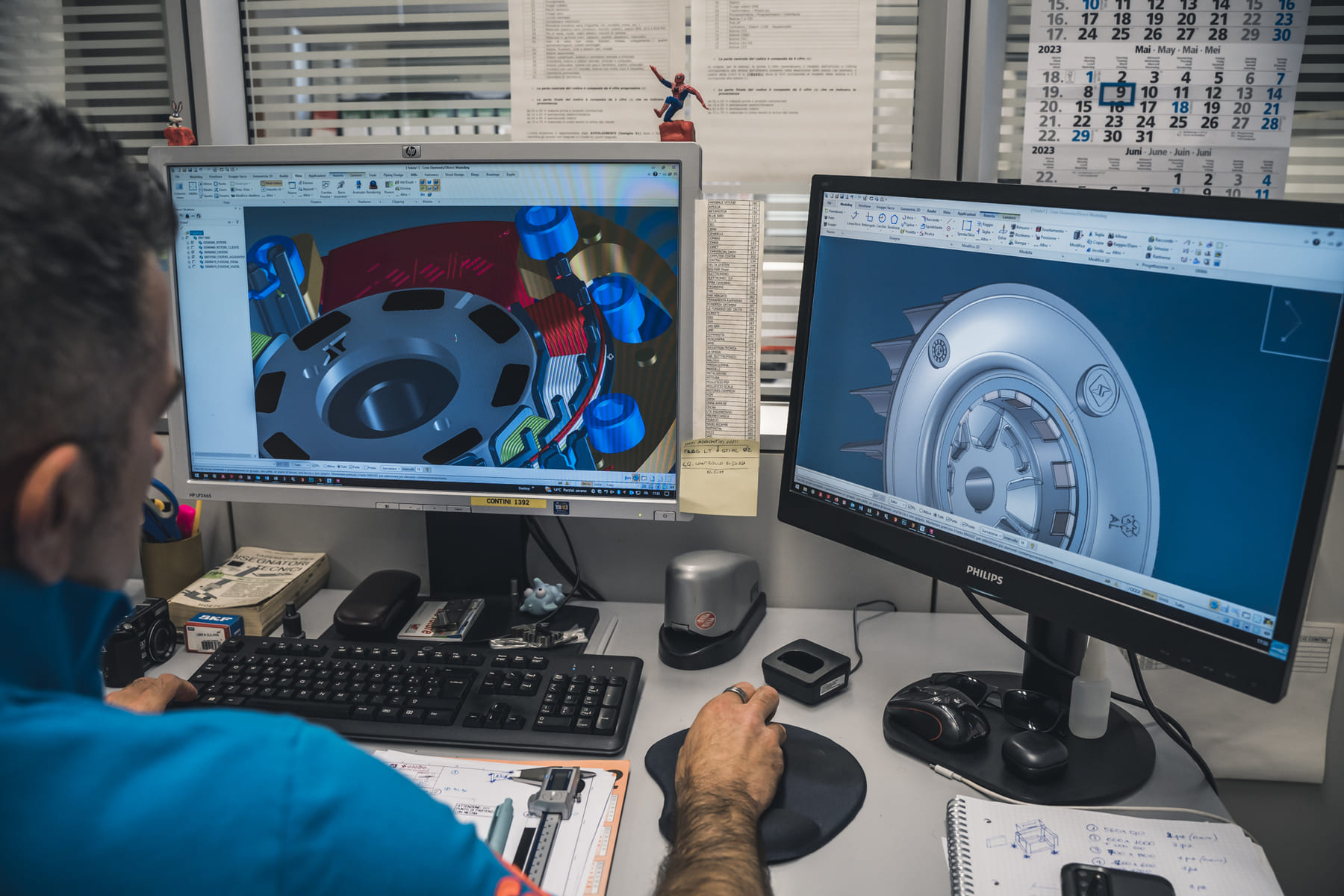

How are we organized?

We are independent in every stage of the component production process. We can handle both small production lots and large job orders, as well as various levels of customization.

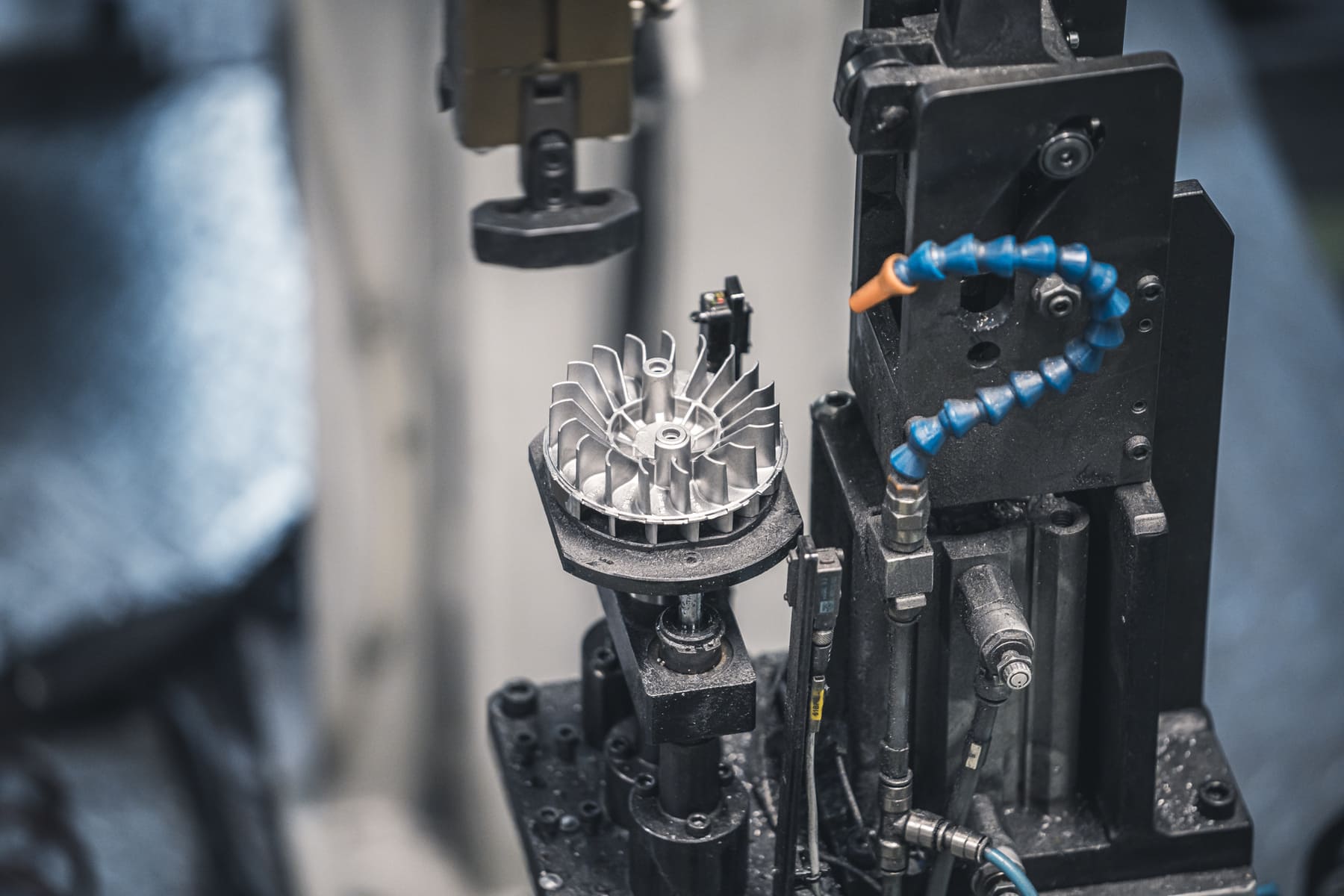

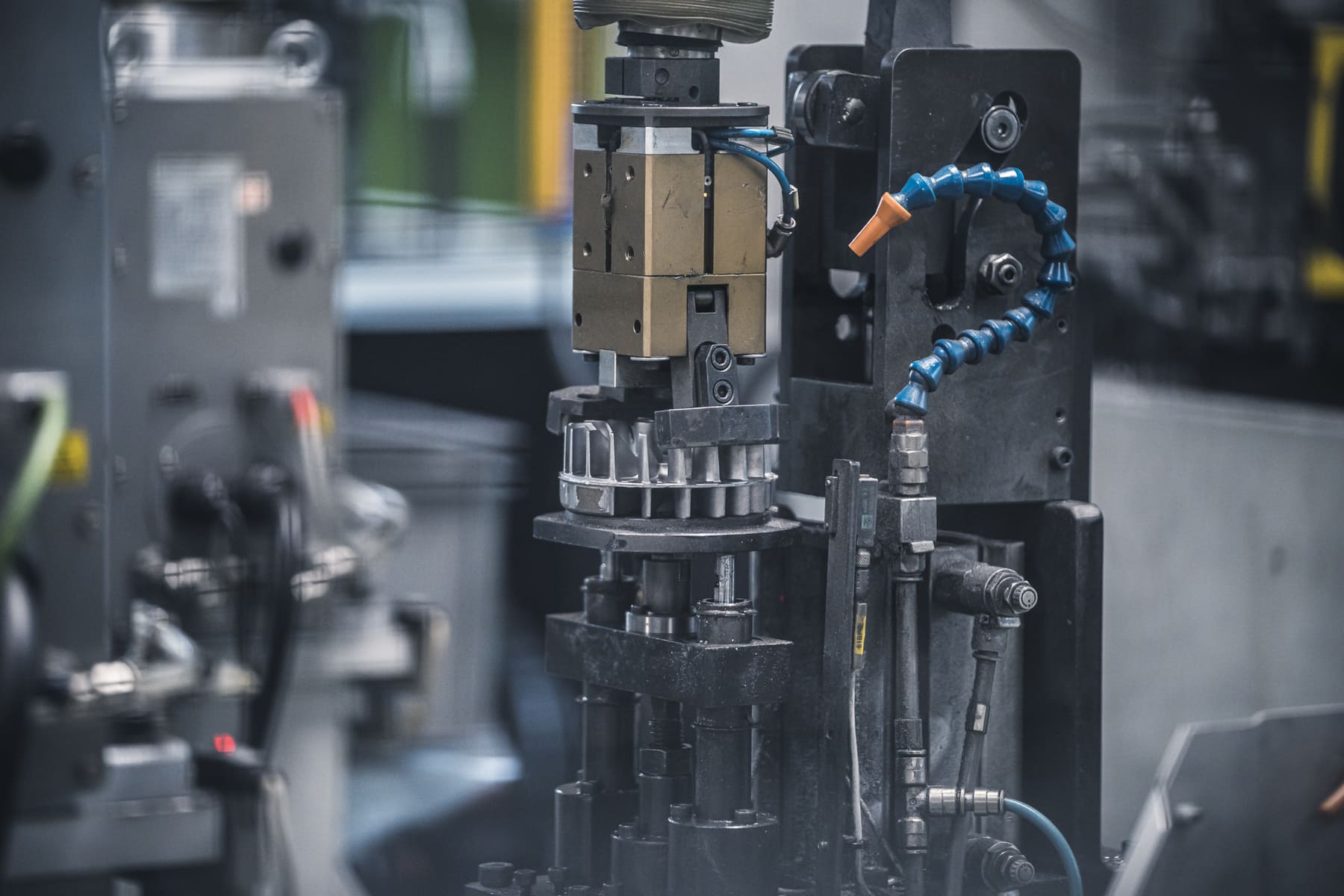

Die-cast aluminium

We have robotized lines able to produce over 25,000 die-cast workpieces a day. We are also able to create all the fixtures required for production, including: die-casting dies, shearing heads and vibratory feeding systems for inserts. In the majority of cases, the fixtures are built by qualified and certified out-sourced manufacturers

We manufacture customized die-cast products

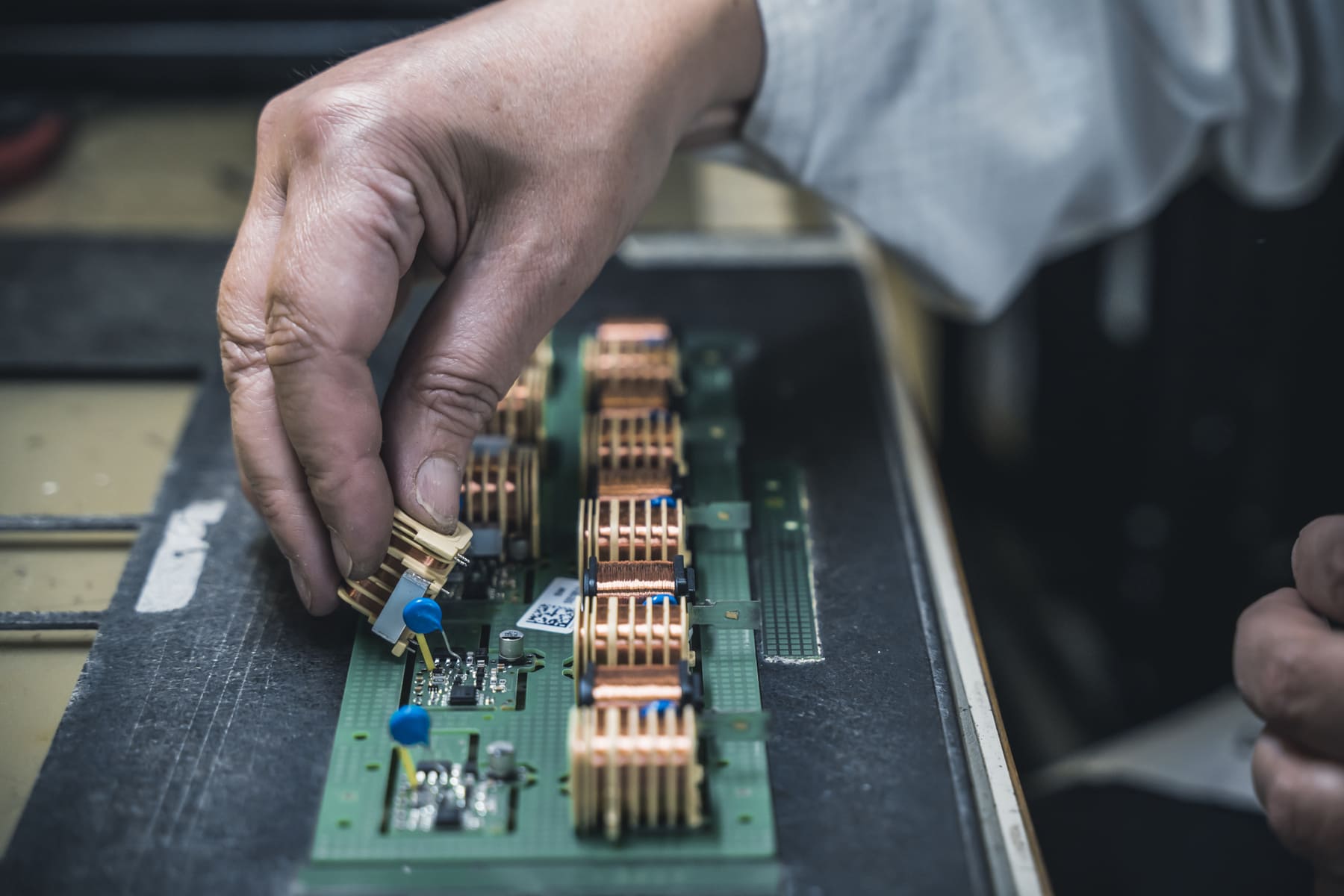

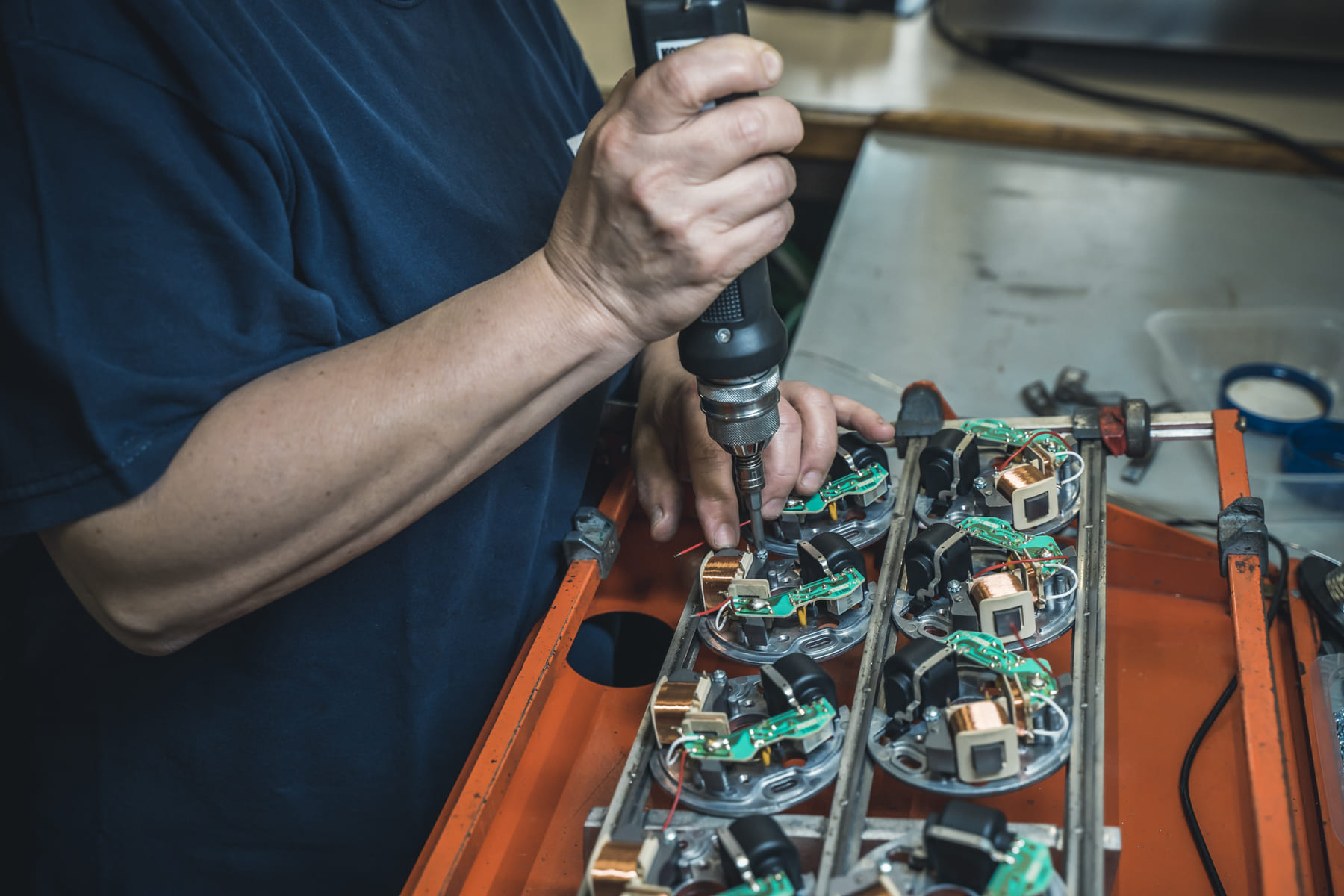

Electronic equipment

The qualified personnel in our electronics department handle each stage of the production process for ignition units, which are then subjected to stringent functional tests.

We also cooperate with CIK-FIA and FMI.

Product control that makes the difference

We employ cutting-edge technologies to accurately monitor the quality of our materials and processes. This is how we are sure of offering our Italian and international customers safe, highly performance-oriented products.

We know that each component must be precise, sturdy and safe

We check each detail with care